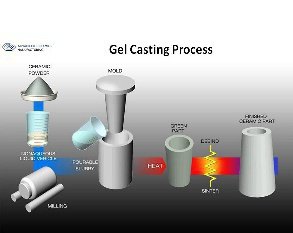

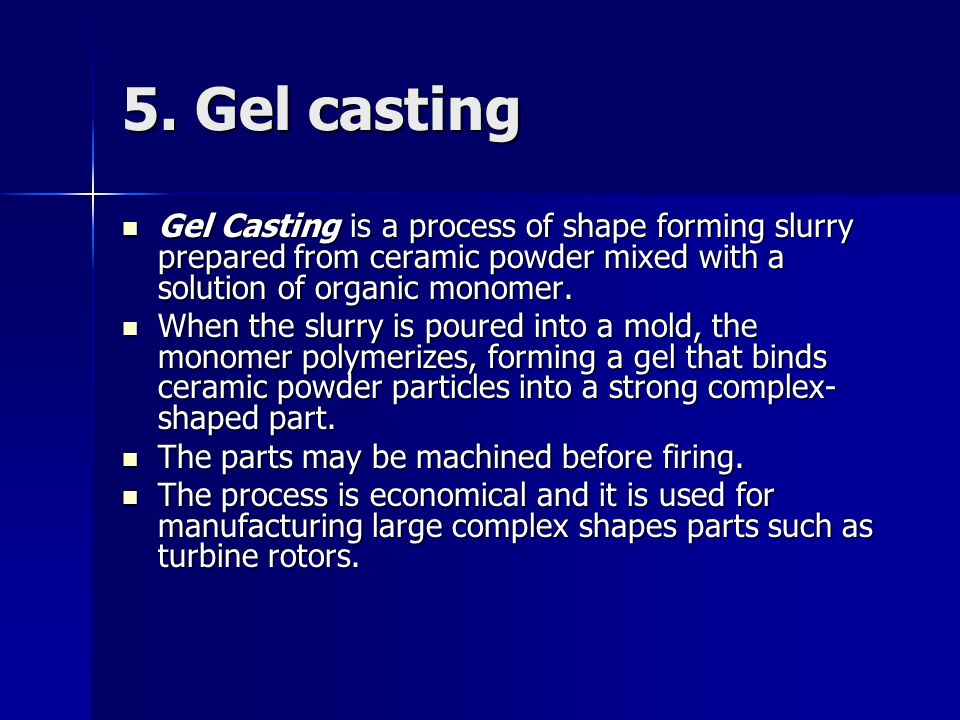

In gelcasting a slip of ceramic powders in a solution of organic monomers is poured into a mold and is polymerized forming a strong crosslinked solvent polymer gel filled with the ceramic powder.

What is gel casting of ceramics.

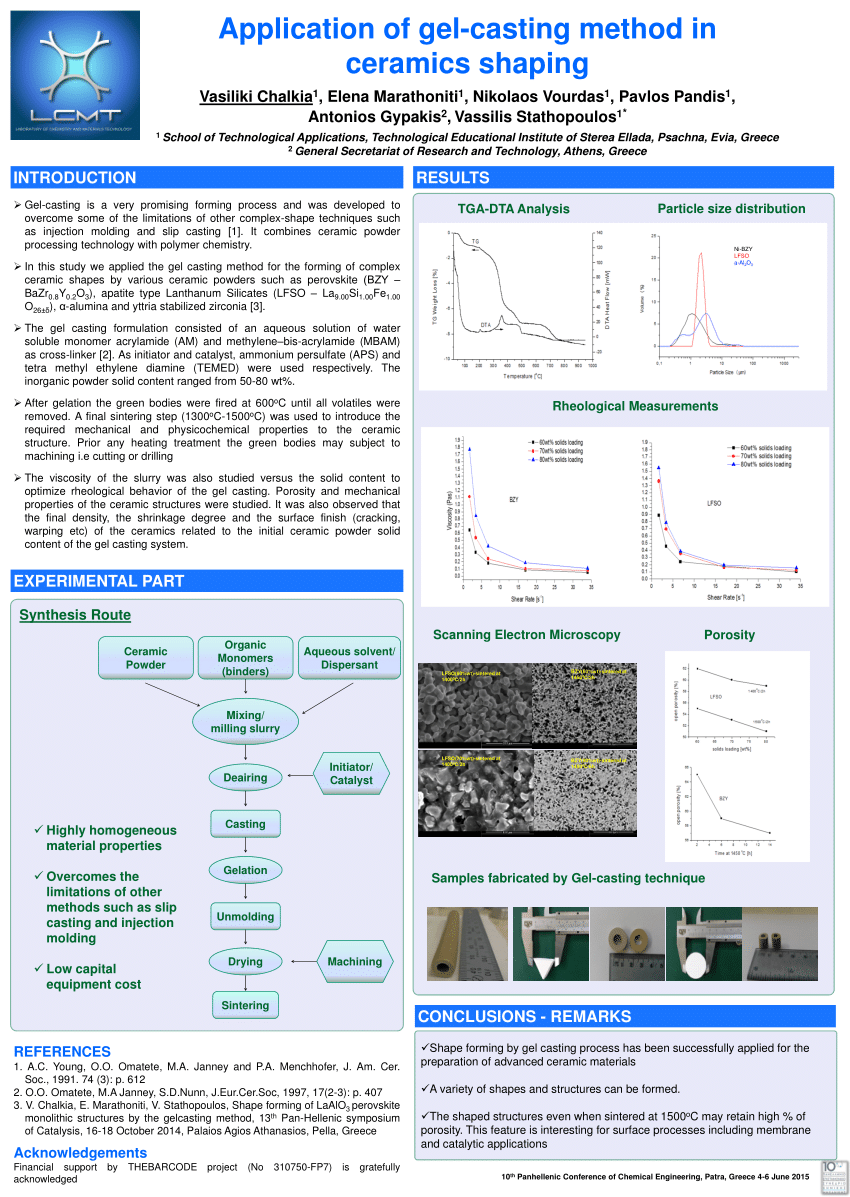

Gel casting is a novel ceramic forming process for fabricating products of complex shaped ceramics.

Gel casting using multi gel caster.

Gel casting using multi gel caster.

Based on gel tape casting another novel process spray inducing instant solidification of gel tape casting was developed to overcome the limitation of the operating time.

In this paper gel casting of silicon powder is investigated.

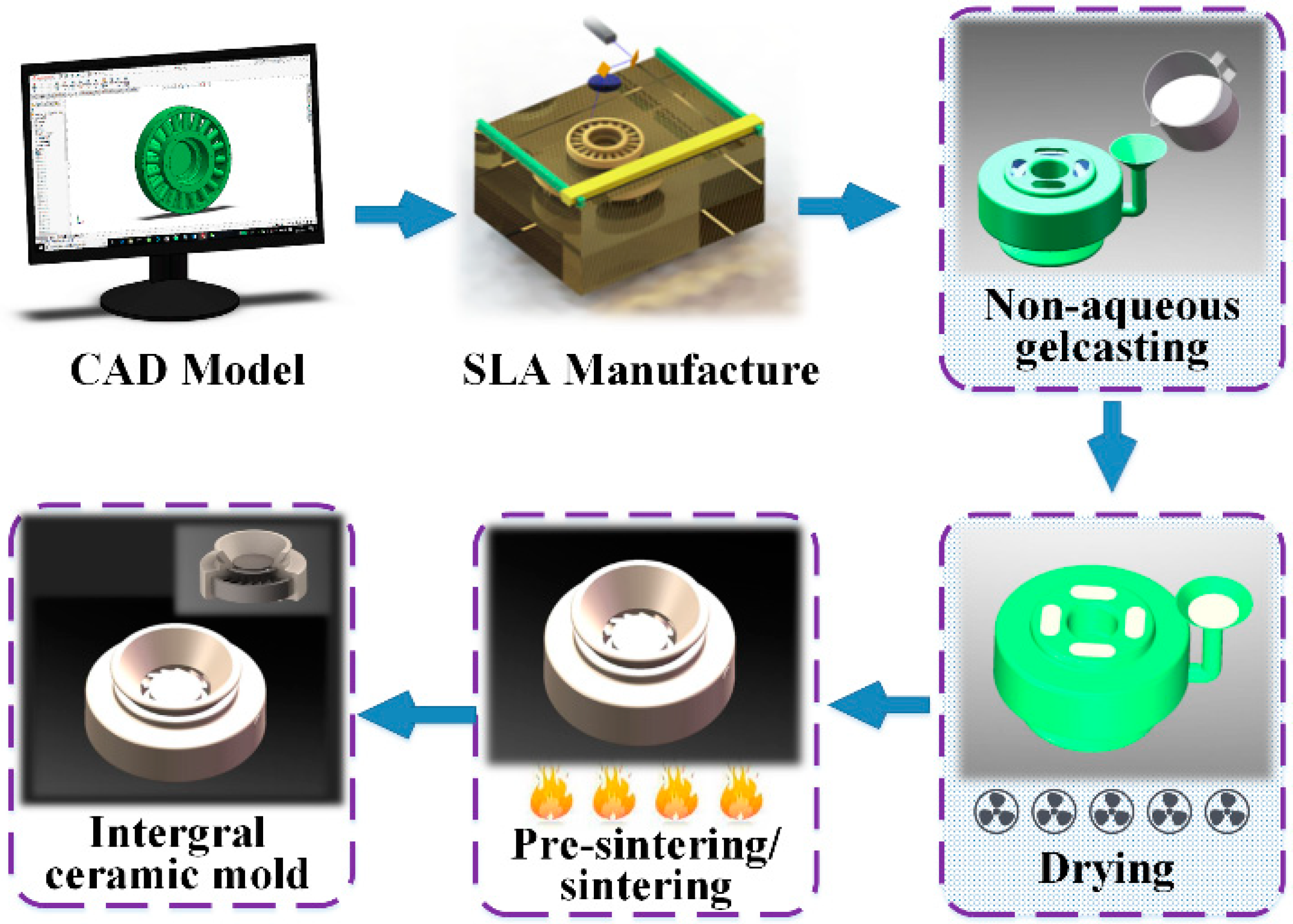

In this contribution the gelcasting process is applied to manufacture green body of ceramic components for microwave resonators oscillators and antennas.

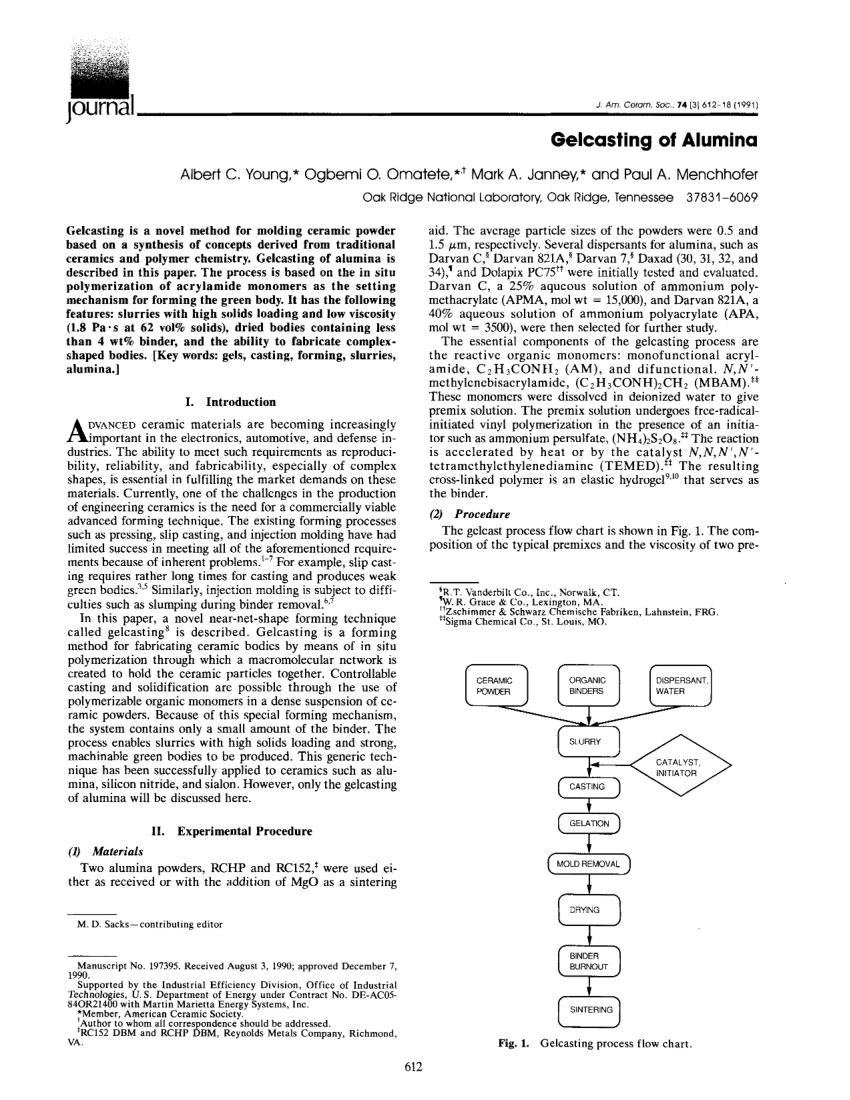

Gel casting is a novel method for moulding ceramic powder based on concepts derived from traditional ceramics and polymer chemistry.

Information a glance.

This process is fit for forming of ceramic sheets with thickness less than 0 3 mm.

The first requirement of the gel casting process is to start from a suspension 45.

Solid loading of slurries.

Skip navigation sign in.

Tony hansen recommended for you.

If a high solid loading is achieved at a low viscosity of the slurry geometrically stable bodies are obtained with low shrinkage by pressureless casting at room temperature consolidation.

Contents on the cd rom.

It is based on the in situ polymerization of acrylamide monomers as the setting mechanism for forming the green body.

Generally the gel casting process includes dispersion of a ceramic powder in a monomer solution to form a slurry which is subsequently gelled in a mould to form a homogeneous wet green body 13.

Reactive organic monomers used for polymerization are one of the key components of this process.

Costs and improves performance gelcasting is an approach of liquid shaping where a few percents of a polymerizeable binder are added to the ceramic slurry.

Factors affecting the performance of ceramic slurries can be summarized as follow.

Alumina ceramic with controlled porosity and small pore sizes of 3 μm can be successfully fabricated via a novel and facile n n dimethylformamide based gel casting technology without using.

How to gel a ceramic glaze duration.

Gelcasting is a forming process similar to slip casting for making complex shaped parts.